Homosexual Audacity Strikes Again: or, learning an entirely new traditional craft

Math. So much math.

For what? A special edition of The Story of the Hundred Promises. We’re talking cloth-bound hardcover. It’s gonna be shiny. It’s gonna have art. It’s going to be everything my starry-eyed little self wanted when I pictured my first published book.

Because of who I am as a person, I don’t just want this to be a bare-minimum, throw-some-glitter-on-it afterthought to get money out of people who have already bought my book. I want to create a truly beautiful book-as-object that reflects my love of books, my interest in traditional crafts, and my desire to combine quality with cost-effectiveness.

This is a journey I’m happy to go on alone, but I’d love to bring you with me.

Step One: Would I even like doing this?

I started off getting quotes from full-service printers. Suffice it to say that either the price was prohibitive for a small run, or the quality left something to be desired. Fortunately, I’d seen the recent explosion of paperback-to-hardcover conversions across the bookish internet. It turns out that it isn’t just homosexual audacity whispering that I could totally do that—the process of bookbinding, especially paperback-to-hardcover conversion, is pretty straightforward.

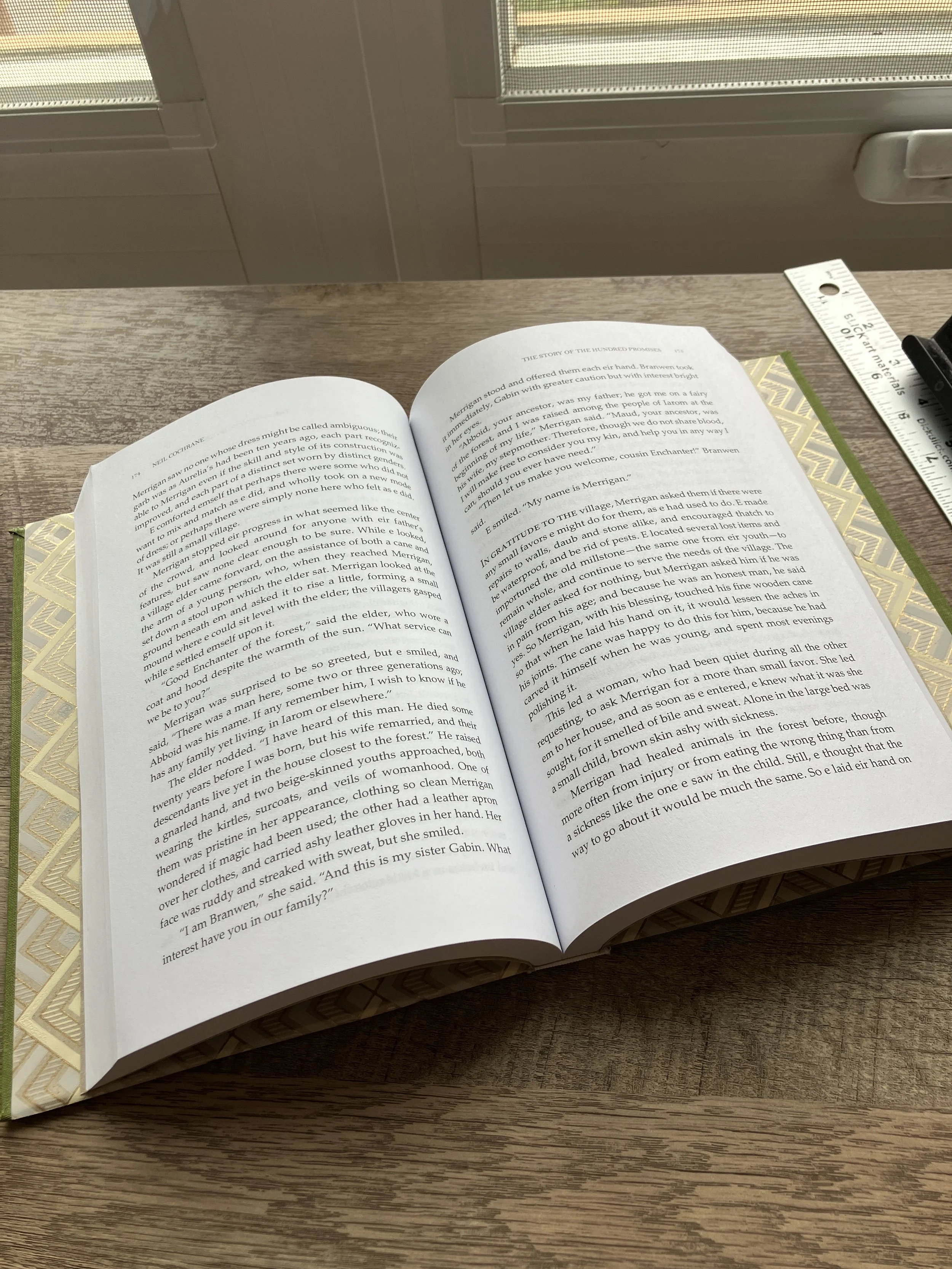

The first step was to actually try it. I decided to try converting my original proof copy of The Story of the Hundred Promises, from April of 2022. It was from before the cover was finalized, so it only had a plain white cover, which felt much easier to rip off than the beautiful purple cover by Gigi Little.

The primary costs for bookbinding are a) pages, also known as a text block, b) chip/davey/binder’s board, the high-density composite that forms the covers and spine, c) cloth or paper to cover the board, and d) endpapers. The other tools and materials, such as glue and mull cloth or super (for spine reinforcement), become negligible in a per-book breakdown. Plus, I already had virtually everything on that ancillary tools list—I was even able to substitute the mull cloth, an open-weave cotton, for some faux-horsehair interfacing.

Materials b, c, and d can be found pretty cheaply on certain evil overlord websites, which I wanted to avoid, so I bought instead from Artist & Craftsman Supply, my local. Lineco is the most common brand I’ve seen in art supply stores, though not necessarily the cheapest. I went ahead and got binder’s board (I bought .067 thickness, though .090 is recommended, since I knew I’d be cutting at home) for $22.80 and bookcloth for $10.70. I also bought some fancy paper for the endpapers, a 22x30” sheet for $5.75.

Doing the binding was really cool. Aside from just how hard the board was to cut (about which I had been warned), it was easy—the hardest part is being careful with the glue, which, for this proof of concept, I didn’t bother to be. I made one calculation error, which was forgetting to add a 1/4” to the top and bottom of the board so that the cover is slightly taller than the text block and the endpapers. Otherwise, it turned out super well and proved that this—binding my own special editions—is completely possible.

Once I’d made one, I could calculate how many I could make out of the materials I’d gotten. The board I’d purchased came in a pack of three and could produce 6 cover sets (front, back, spine), at a cost of $3.80 per book. I could only get one cover out of the book cloth, which was a single 17x19” sheet. Lineco’s website showed a 17x38” option for $13.90, which would produce two covers at $6.95 per book.

So, it became pretty clear that aside from the text blocks, book cloth was likely to be the second largest expense. You can technically use any kind of cloth, but ideally, it is paper-backed to allow the glue to adhere without seeping through to the front.

Luckily, it’s pretty easy to make with any fabric you choose. All you need is paper and a way to adhere it to the fabric. Most of the hobby re-binders I’ve seen use HeatnBond, an iron-on backing. I found another tutorial using Japanese rice paper and wheat paste, which is even more cost-effective at scale—one roll of rice paper I found was enough for 42 6x9” hardcovers, coming out to $0.50 per book.

From there, the cost depends on the kind of fabric chosen. I would love to go with something 100% linen, but the floor for such fabric is around $24/yard these days. One option I found at that price would yield 9 6x9” book cloths at $2.66 per book. Add the fifty cents for the rice paper, and you get $3.16 per book.

So: the next step is to attempt making my own book cloth!